Solvent Recycling Machine

Recycle over 90% of solvents and cut costs with HongYi’s advanced solvent recycling machines — delivering sustainable, high-ROI solutions for your factory.

Find the Right Solvent Recycling Solution for Your Needs

Whether you’re seeking an affordable entry-level model, an automated continuous system, or a fully customized high-end solution — HongYi offers a complete range of solvent recycling machines to meet every industry need.

Basic Series of Solvent Recycling Machine

The basic models of HongYi solvent recycling machines are cost-effective and ideal for small to medium-sized factories. Designed for manual batch operation, they are a reliable choice for customers who value high cost-performance and rapid implementation. Optional automatic feeding systems are available for continuous recycling needs.

- Capacity options: Hy20Ex, Hy60Ex, Hy90Ex, Hy125Ex

- Manual feeding and residue discharge

- Compact design, easy to operate and maintain

Continuous Operation Series

This series is designed for continuous solvent recycling processes. Equipped with automatic feeding and residue discharge, it’s ideal for industries requiring high efficiency and low labor input.

- Models available: Hy60Ex-A, Hy90Ex-A, Hy125Ex-A, Hy250Ex-A, Hy450Ex-A, Hy600Ex-A

- Continuous operation with auto feeding & residue discharge

- Reduced downtime and labor cost

- Ideal for medium to large-scale production lines

Customized High-end Pro Series

High-end customized solvent recycling machines for factories with strict requirements on process control, safety, and system integration. Fully tailored to meet specific industrial needs.

- Models available: Hy250Ex-V, Hy450Ex-V, Hy600Ex-V

- Optional liquid ring or pneumatic vacuum systems

- Optional stirring functionality for better heating and mixing

- Support for other customized functions per project requirements

- Large capacity up to 500+ liters, explosion-proof and ATEX optional

From Waste to Wealth: Solvent Recycling System

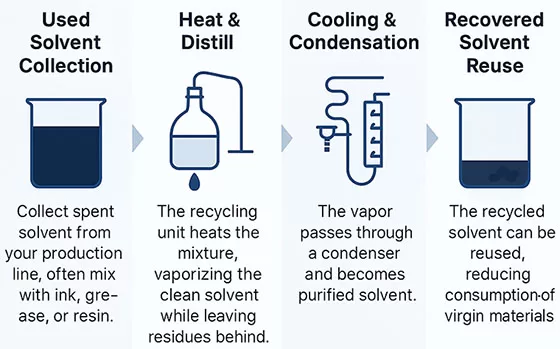

How It Works:

Turn spent solvents into valuable resources.

Our system uses distillation technology to separate contaminants from used solvents. Clean solvents are recovered and reused in production, significantly reducing both waste and raw material costs.

Why It Matters:

- Up to 90% Solvent Recovery Rate

- Reduce Waste Disposal Costs

- Save on Raw Material Purchases

- Lower Environmental Impact

Turn Your Trash into Cash

The payback period of the recycling machine only need half or one year.

Reduce the purchase of new solvents

Effectively reduce the demand for new solvents, obvious savings in procurement costs

Reduce the cost of waste solvent treatment

Self-treatment of waste solvents avoid high third-party treatment costs, and effectively save costs

Improve the cleaning performance

Relatively strict amount control, sufficient clean solvent is conducive to improve the high cleaning effect of workpieces or tools

Enhance recognition of the enterprise

Energy saving, environmental protection and resource reuse are not only supported by the government, but also recognized by customers.

Care About What You Care About

Smart and Safe: The intelligent features of modern solvent recycling systems

Safety First

Explosion-proof design for secure operation.

Air-cooling System

Stable cooling without external water source.

Intelligent & Continuous

Supports automatic feeding and continuous distillation.

Multiple Solvent Compatibility

Handles acetone, thinner, ethyl acetate and more.

Easy Maintenance

Built-in cleaning features and maintenance reminders.

Plug & Play, Easy Setup

Quick installation and startup with minimal training.

Frequently Asked Questions (FAQ)

- What solvents can your machines recover?

- Our machines can recover acetone, thinner, ethyl acetate, and most common industrial solvents.

- How long is the return on investment (ROI)?

- Depending on solvent volume, many clients see ROI within 6–12 months.

- Do you offer explosion-proof certification?

- Yes, all machines come with explosion-proof configuration for safe industrial use.

- Can I automate the feeding process later?

- Yes, our Basic Series supports future upgrades for automatic feeding systems.

- Is technical support available?

- We provide full technical support and documentation, plus consultation from our engineering team.