Solvent Recovery System

Meet the Highest Standards While Remaining Affordable and Easy to Install

Reduce waste and cut costs with our easy-to-install, high-efficiency solvent recovery solutions. Whether you need a basic, budget-friendly model or a fully customized unit that meets stringent industry standards, we can help.

Solvent Regeneration: Turning Waste into Wealth

By heating used cleaning solvents, our system separates valuable liquids from resins, oils, and paint residues. As a result, you recover up to 95% of usable solvent.

Investing in a solvent recovery equipment is a smart choice for businesses aiming to improve efficiency, save costs, and reduce environmental impact. Consequently, your solvent purchase costs drop dramatically while waste disposal fees decrease by over 90%. This not only saves money but also helps you meet environmental standards.

Solvent Recovery System Series

Basic Series

- Single-batch Basic models

- Manual feeding required

- 2 to 3.5 hours per cycle

- Cost-effective

- Easy to install and operate

- Simple to maintain

- From 20 to 125 liters in a single batch

The equipment is equipped with expansion interfaces and software for material feeding, allowing customers to enhance their systems post-purchase with automated feeding components for 24/7 unattended operation.

| Models | Hy20Ex | Hy40Ex | Hy60Ex | Hy90Ex | Hy125Ex |

|---|

- Pneumatic Vacuum device

- Feeding device

- Liner bags

- Water-cooling

- Bottom drainage slag-off

- Customizable voltage

Advanced Continuous Series

- Continuous running models

- Fully automated feeding

- Mid-process replenishment

- Significantly less manual work/operation

- 3 to 24 hours automatic operation

- Hourly capacity from 30 to 150 liters

| Models | Hy60Ex-A | Hy90Ex-A | Hy125Ex-A | Hy250Ex-A | Hy450Ex-A | Hy600Ex-A | Hy1000Ex-A |

|---|

- Pneumatic Vacuum device

- Liner bags

- Water-cooling

- Bottom drainage slag-off

- Customizable voltage

High-end Customized Series

Engineered solutions for strict compliance and large volumes. Options include explosion-proof design, nitrogen blanketing, and process integration.

- HongYi's flagship product

- For large-scale, demanding customers

- Equipped with the latest technology

- Focus on safety and quality

- Customizable industrial solvent recovery

- Conical distillation tank

- Pneumatic bottom discharge slag Removal

- SS316 spiral-wound tubular water-cooling system

- Hourly capacity from 30 to 150 liters

| Models | Hy125Ex-L | Hy250Ex-V | Hy450Ex-V |

|---|

- Pneumatic vacuum

- Liquid Ring vacuum

- Stirring Function

- Heating oil Rapid Cooling

- Nitrogen Protection Function

- Customizable voltage

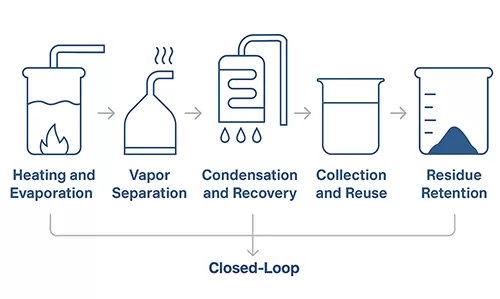

How Solvent Recovery Equipment Works

- Heating and Evaporation: Waste solvent is heated in the distillation tank until it reaches the boiling point and vaporizes.

- Vapor Separation: Solvent vapor rises and moves into the cooling system.

- Condensation and Recovery: The vapor condenses into liquid in the cooling system.

- Collection and Reuse: The recovered solvent is collected and reused in production.

- Residue Retention: Impurities like paints and resins remain in the tank for disposal.

By heating used solvents to their boiling point, the closed-loop process separates and recycles valuable solvent materials. As a result, it helps reduce solvent waste and lower disposal costs. Consequently, environmental sustainability is promoted.

Solvent Recovery System Features

User-Friendly

Most models require only electricity, compressed air, and water. Additionally, installation and operation remain straightforward. As a result, on-site service is rarely needed.

Clear Status Display

Featuring real-time monitoring, fault diagnosis, alarms, and maintenance reminders, the display provides up-to-the-second operating data. Consequently, users can run the recovery system with greater confidence and minimal downtime.

Omron Temperature

Thanks to Omron’s multi-stage temperature and time control, you can precisely preset heating parameters at each phase. As a result, the recovery process remains both efficient and highly accurate.

One-button Start

By using its one-button start, the machine can run unattended for up to 24 hours, thereby streamlining operations and boosting productivity. Furthermore, you can customize the runtime to match your exact requirements.

Get Your Free for Solvent Recovery Feasibility Report

What’s Included:

- Customized solution to fit your requirements

- Technical specification

- Application case studies

- Industry-specific solutions

- Complimentary feasibility assessments, tailored to your:

- Production processes

- Solvent types

- Recovery volume

- Budget

We understand that each business has unique solvent recovery needs. By working with our experts, you’ll receive tailored insights—whether you need a quick overview or an in-depth technical solution.

Frequently Asked Questions

What types of solvents can your machines recover?

Our systems can recover a wide range of organic solvents, including alcohols, ketones, esters, and hydrocarbons.

How long does installation take?

Basic models can be installed in just 1–2 days. Customized systems may require a site evaluation.